About LAMY

The launch of the LAMY 2000 Fountain Pen in 1966 was a defining moment in LAMY history. Though the LAMY name first appeared in 1952, the arrival of the LAMY 2000 defined the pen maker in a way that still holds true today.

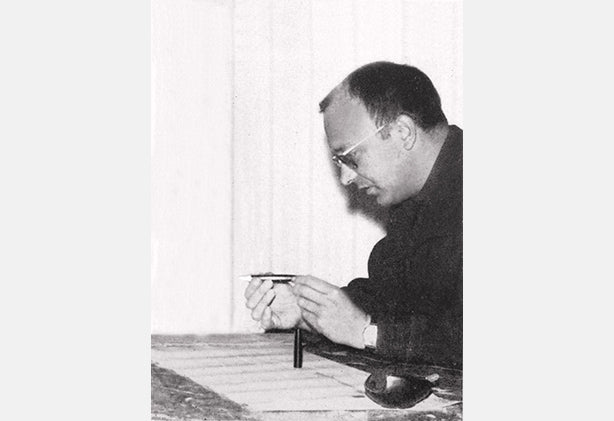

Designed by Gerd Alfred Müller, the LAMY 2000 was shaped by the Bauhaus philosophy, “form follows function”, the practical simplicity of the fountain pen became the foundation upon which LAMY’s clear, essential design language still rests more than 55 years later.

If the LAMY 2000 was a big milestone for the brand, the arrival of the LAMY safari in 1980 was a landmark for the entire pen industry. Designed with schoolchildren in mind, the safari’s rugged ABS body and ergonomic grip quickly made it the world’s best-selling fountain pen.

Alongside new developments in writing instruments, LAMY has continued to innovate behind the scenes. With an ever-advancing factory system that means roughly 95% of production happens on-site, including the capacity to produce its own ink, LAMY is always working on ways to improve.